By harnessing advanced 3D technology, we unlock new precision, customisation, and efficiency levels. Our innovative solutions streamline the mold design and manufacturing process, enabling faster production cycles, reduced costs, and enhanced quality.

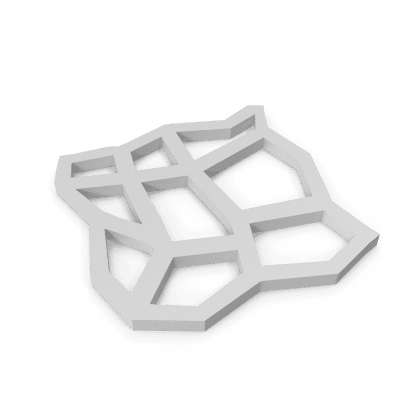

Our team of experts collaborates closely with concrete professionals to develop tailor-made solutions that meet their specific requirements. With our advanced 3D modelling and printing capabilities, we transform design concepts into highly detailed, accurate, and durable concrete molds. By leveraging the power of 3D technology, we enable the creation of intricate and complex shapes, textures, and patterns that were once unimaginable.

With our advanced 3D modeling and printing capabilities, we transform design concepts into highly detailed, accurate, and durable concrete molds. By leveraging the power of 3D technology, we enable the creation of intricate and complex shapes, textures, and patterns that were once unimaginable.

Redefining concrete mold manufacturing with 3D solutions

The mold design is created using advanced 3D modeling software based on your project’s specifications. This digital design helps deliver precise, detailed molds that meet your requirements.

The digital design is sent to a 3D printer, which constructs the mold layer by layer. This additive manufacturing process enables the creation of complex 3D-printed molds for concrete casting that would be challenging to produce using traditional methods.

Several concrete 3D printing technologies are used in the production of concrete casting molds:

The printed mold may undergo finishing processes to reinforce its strength and surface quality. These post-processing steps ensure that the mold is durable and ready for use in concrete casting.

The completed mold is used to cast concrete, resulting in precise and detailed concrete structures. This method ensures that each cast is consistent and meets the project’s unique specifications.

At Inoventive 3D, we thrive on precision and ensure that your vision is brought to life down to the most minute details. This requires 3D-printed molds for concrete casting that push the boundaries of what is possible with 3D mold design. When the modeling is complete, our printers allow us to produce a product that perfectly mirrors your designs.

3D printing has entirely changed how we produce molds for concrete casting. Traditional mold-making methods were resource-heavy. 3D printing streamlines the process and produces molds directly from digital designs. This speeds up the production process and dramatically reduces the risk of errors and inconsistencies.

There are several benefits of using 3D-printed molds for concrete casting:

We need to collaborate closely with you as a client to understand your requirements. Our advanced 3D modeling software creates highly detailed and accurate designs. This level of precision is important, as even the slightest deviation can impact your final structure.

Due to the use of high-quality materials, our 3D-printed molds for concrete casting offer exceptional quality and durability. Pre-cast materials are proven to be more resistant to the elements and external factors like fire, insects, or mold. The final products are strong, extremely resistant to wear, and capable of standing the test of time.

3D printing of concrete is a useful method for creating molds for concrete facades. Architects are given the tools needed to create visually stunning designs that provide a unique component to the building’s appeal. Perhaps, even more importantly, each facade component will fit perfectly, improving the quality of the finished structure.

3D-printed molds for concrete casting open the door to big and small architectural innovations. This can apply to everything from decorative features to major structural components; molds can be created in any shape or size. The flexibility of 3D printing allows architects to push the boundaries of creativity and design. The technology can create everything from walls, stairs, and infrastructure to indoor and outdoor furniture.

A significant advantage of 3D-printed molds for concrete casting is the environmentally friendly nature of the manufacturing method. It minimizes material waste by using only the exact amount of material needed for each mold. Additionally, many 3D printing materials are eco-friendly and recyclable, adding further to sustainable construction practices.

Inoventive 3D is dedicated to leading the way in mold manufacturing and continually reimagining what is possible with 3D printing technology. We deliver what you need with the highest-quality molds for your construction projects. Whether it’s architectural facades, decorative elements, or infrastructure projects such as bridges and tunnels, the versatility of 3D printing allows for innovative design solutions across industries and applications.

Send your inquiries here or can Email us on info@inoventive3d.com or can Call us on +971 58 658 6675